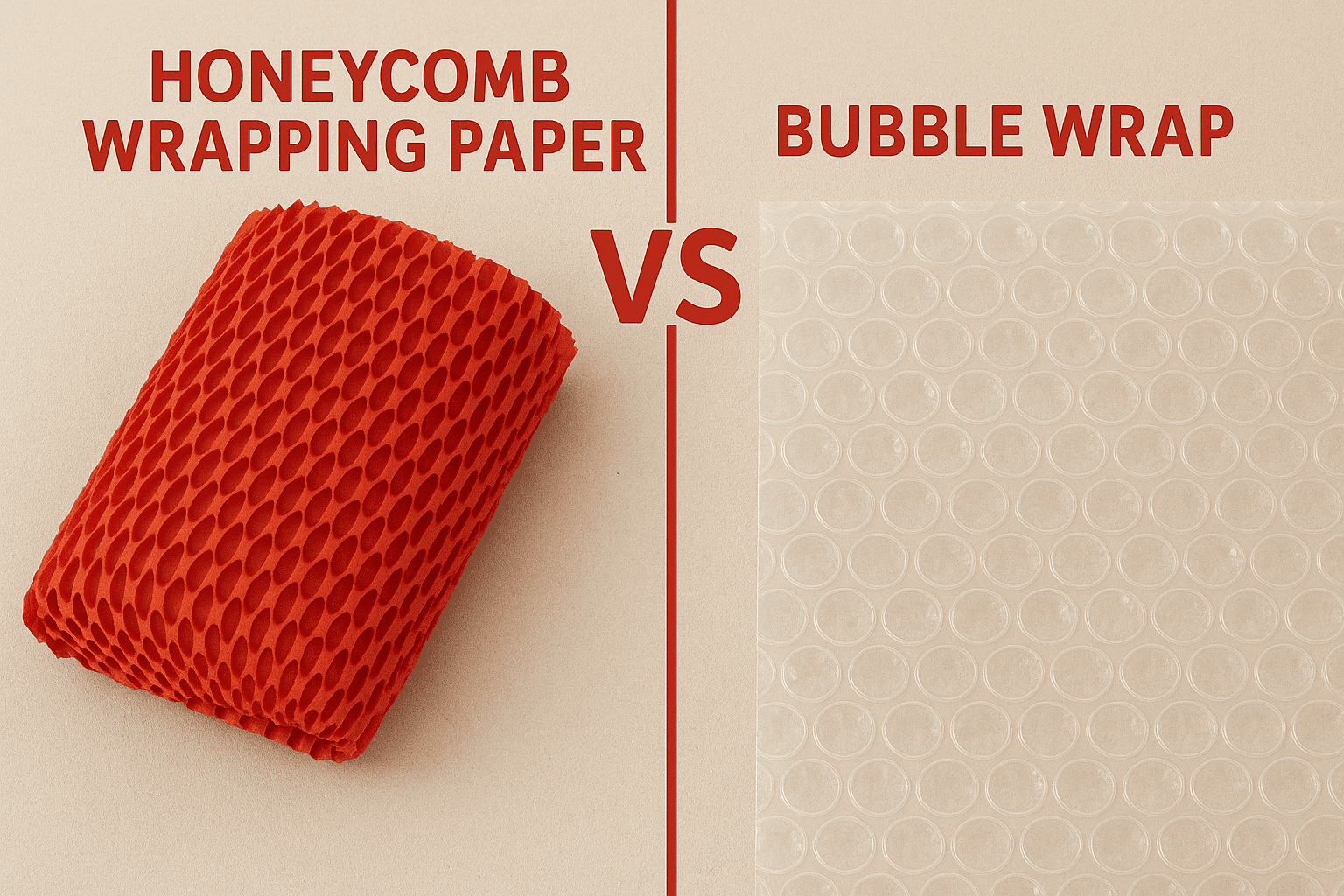

Honeycomb Vs Bubblewrap

Honeycomb Packing Paper vs. Bubble Wrap: A Comprehensive Comparison

Introduction

In the packaging industry, businesses and consumers alike seek materials that provide optimal protection for shipped items while also considering cost, environmental impact, and ease of use. Two of the most commonly used materials for protective packaging are honeycomb packing paper and bubble wrap. While bubble wrap has long been a popular choice for cushioning fragile goods, honeycomb packing paper has emerged as an eco-friendly alternative that offers similar protective qualities.

This article provides an in-depth comparison between honeycomb packing paper and bubble wrap, focusing on aspects such as protection, environmental sustainability, cost, usability, and versatility.

1. Protective Capabilities

Honeycomb Packing Paper

Honeycomb packing paper consists of interwoven paper layers designed in a hexagonal pattern, resembling a beehive structure. This structure provides excellent shock absorption and flexibility while keeping products securely in place. Key protective benefits include:

Shock Absorption: The honeycomb pattern disperses impact force, minimizing damage.

Flexibility: Can be wrapped tightly around objects, conforming to different shapes.

Surface Protection: Prevents scratches and abrasions on delicate items such as glass, ceramics, and electronics.

Bubble Wrap

Bubble wrap is made of plastic sheets containing air-filled bubbles that cushion fragile goods. Protective benefits include:

Cushioning Effect: The trapped air within the bubbles absorbs shocks and impacts.

Superior Padding: Ideal for heavy and extremely fragile items.

Multiple Thicknesses: Available in different sizes for varying levels of protection.

Comparison

While both materials provide effective protection, bubble wrap generally offers better shock absorption for extremely fragile items. However, honeycomb packing paper is more flexible and provides excellent surface protection without static buildup, which can be an issue with bubble wrap when shipping electronics.

2. Environmental Impact

Honeycomb Packing Paper

Biodegradable: Composed entirely of recyclable and biodegradable materials.

Sustainable Sourcing: Often made from recycled paper and can be easily recycled again.

Plastic-Free: Does not contribute to plastic pollution.

Bubble Wrap

Non-Biodegradable: Made from polyethylene, which takes centuries to break down.

Difficult to Recycle: Requires specialized recycling facilities, and many municipalities do not accept it in curbside programs.

Environmental Concerns: Contributes to plastic waste and ocean pollution.

Comparison

Honeycomb packing paper is the clear winner when it comes to environmental sustainability. With increasing regulations and consumer demand for eco-friendly solutions, many businesses are shifting away from plastic packaging materials like bubble wrap in favor of biodegradable options.

3. Cost Efficiency

Honeycomb Packing Paper

Lower Material Cost: Generally more affordable per unit compared to high-quality bubble wrap.

Space-Saving: Takes up less storage space than bulky bubble wrap rolls.

Less Waste: Can be reused or recycled easily, reducing overall waste disposal costs.

Bubble Wrap

Higher Initial Cost: High-quality bubble wrap can be expensive.

Storage Challenges: Requires significant space for storage due to bulky rolls.

Non-Reusable: Once popped or torn, it loses its protective capabilities.

Comparison

Honeycomb packing paper is often the more cost-effective option, particularly for businesses looking to minimize packaging expenses and storage requirements.

Usability and Convenience

4. Usability and Convenience

Honeycomb Packing Paper

Easy to Cut and Wrap: Can be torn or cut without additional tools.

Lightweight: Does not add significant weight to shipments.

Non-Static: Safe for wrapping electronics without generating static electricity.

Interlocking Structure: No need for adhesive tapes in some applications.

Bubble Wrap

Pre-Cut Sheets Available: Convenient for large-scale packaging operations.

Bulky and Difficult to Store: Takes up more space in warehouses.

Requires Tape: Often needs additional securing with packing tape.

Comparison

Honeycomb packing paper is easier to use, especially for businesses that require quick and efficient packaging solutions. The need for less tape and additional materials also makes it a preferred choice for high-volume shipping operations.

5. Versatility in Applications

Honeycomb Packing Paper

Ideal for E-commerce: Provides an eco-friendly packaging solution for small businesses.

Gift Wrapping and Presentation: Aesthetic and elegant appearance, often used in premium packaging.

Product Protection: Commonly used for electronics, glassware, and ceramics.

Bubble Wrap

Heavy-Duty Packaging: Suitable for industrial shipments of fragile machinery and equipment.

Temperature Insulation: Provides insulation for temperature-sensitive shipments.

Reusable in Some Cases: Can be used multiple times if not damaged.

Comparison

While bubble wrap is superior for high-impact protection and insulation, honeycomb packing paper is better suited for eco-conscious brands, aesthetically appealing packaging, and small to medium-sized items.

6. Consumer Preference and Market Trends

With the increasing focus on sustainability, many businesses and consumers are shifting towards environmentally friendly packaging solutions. Surveys indicate that customers prefer brands that use eco-friendly materials. Additionally, e-commerce giants and logistics companies are adopting biodegradable packaging to meet sustainability goals.

Conclusion

Both honeycomb packing paper and bubble wrap have their own strengths and applications. While bubble wrap provides unmatched cushioning for highly fragile items, honeycomb packing paper offers superior sustainability, cost-effectiveness, and ease of use.

For businesses and individuals looking to reduce their environmental impact while maintaining effective protection, honeycomb packing paper is the clear choice. However, for situations requiring maximum shock absorption, bubble wrap remains a viable option.

Ultimately, the decision between the two materials depends on specific packaging needs, budget, and environmental priorities.